响应《中国制造2025》油墨、涂料领域研磨设备革新

————砂磨机升级体现在哪?

砂磨机制造业在积极响应中央政策的前提下,华一宝公司本着“两个坚持”的原则,把其中的“质量为先、绿色发展、结构优化、着眼长远、重点突破、自主发展”作为华一宝企业发展的重中之重。为实现制造强国的战略目标,出一份力量。 《中国制造2025》的内容里,包含了十大领域,这些领域与砂磨机有着直接与间接的关系:

一:新材料

大部分新材料需要砂磨机做物理湿法研磨,在新材料湿法研磨过程中,不影响材料的分子结构情况下,唯有物理方式(湿法研磨)才能真正解决材料的广泛用途。

二:新一代信息技术

传感器原材料的湿法研磨、触摸电子屏的原材料研磨、稀土等

三:新能源汽车

锰酸锂、钴酸锂、电池、三元材料、隔膜等

四:生物医药及高性能医疗器械

医药制剂、朱砂、硅粉(药丸填料)等

五:航空航天装备、高档机床和机器人、海洋工程及高技术船舶、轨道交通、农业机械、

电力装备这些行业都离不开高档油漆、涂料、绝缘材料等,与砂磨机都有间接关系。

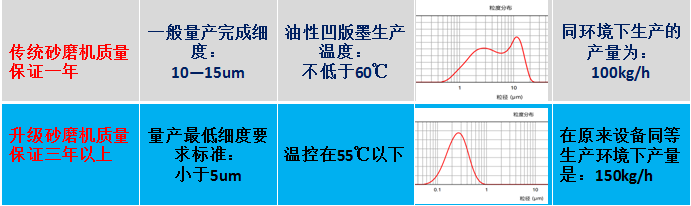

以下就以砂磨机在传统凹版印刷行业的应用升级做个简要比较:

传统砂磨机在研磨介质、出料缝隙环、内转子(主动力)、冷却系统、配件精加工与选材、控制系统等在目前大环境里都相对滞后。

近五年来砂磨机行业如飞的进步速度,砂磨机结构设计、选材、精加工、控

制等已经发生了质的变化。砂磨机制造行业在《中国制造2025》精神倡导中,真正理解了制造业是国民经济的主体、是立国之本、兴国之器、强国之

基。打造具有国际竞争力的制造业是每一个制造业企业的奋斗目标。

广东华一宝升级后的砂磨机,体现在以下五点:

一:为客户产品提升品质

二:体现企业的绿色发展(更环保)

三:立足当前和整体推进突显

四:生产过程中数据管理规范化

五:综合生产能力提升

更多关注:

www.hybint.com

What is the specific embodiment of the fine grinding mill after the upgrade?

Responding to the "Made in China 2025" ink, coating field fine grinding mill innovation

————Where is the upgrade of fine grinding mill?

Under the premise of actively responding to the central policy, Huayibao Company adheres to the principle of “two persistences” and puts “quality first, green development, structural optimization, long-term focus, key breakthrough, and autonomy. Development" is the top priority of Huayibao's enterprise development. In order to achieve the strategic goal of manufacturing a strong country, a force is made. The contents of "Made in China 2025" contain ten major fields, which have direct and indirect relationships with fine grinding mills:

One: new materials

Most new materials require a sand mill for physical wet grinding. In the wet grinding process of new materials, the physical form (wet grinding) can only truly solve the wide-ranging use of materials without affecting the molecular structure of the material.

Second: a new generation of information technology

Wet grinding of sensor raw materials, grinding of raw materials for touch electronic screens, rare earths, etc.

Three: new energy vehicles

Lithium manganate, lithium cobalt oxide, battery, ternary material, separator, etc.

Four: biomedical and high performance medical devices

Pharmaceutical preparations, cinnabar, silicon powder (pill filler), etc.

Five: aerospace equipment, high-end machine tools and robots, marine engineering and high-tech ships, rail transit, agricultural machinery,

Power equipment These industries are inseparable from high-grade paints, coatings, insulation materials, etc., and have indirect relations with fine grinding mills.

Conventional fine grinding mills are relatively lagging in the current environment in grinding media, discharge slit ring, inner rotor (main power), cooling system, accessory finishing and material selection, and control systems.

In the past five years, the progress of fine grinding mill industry such as flying, fine grinding mill structure design, material selection, finishing, control

The system has undergone qualitative changes. In the spirit of "Made in China 2025", the fine grinding mill manufacturing industry truly understands that manufacturing is the main body of the national economy, the foundation of the country, the instrument of rejuvenating the country, and the power of the country.

base. Creating an internationally competitive manufacturing industry is the goal of every manufacturing company.

The fine grinding mill after the upgrade of Guangdong Huayibao is reflected in the following five points:

One: improve the quality of customer products

Second: reflect the green development of the company (more environmentally friendly)

Three: based on the current and overall advancement highlights

Four: Standardization of data management in the production process

Five: comprehensive production capacity improvement

More attention:

Www.hybint.com